Engine Monitoring

Product Range

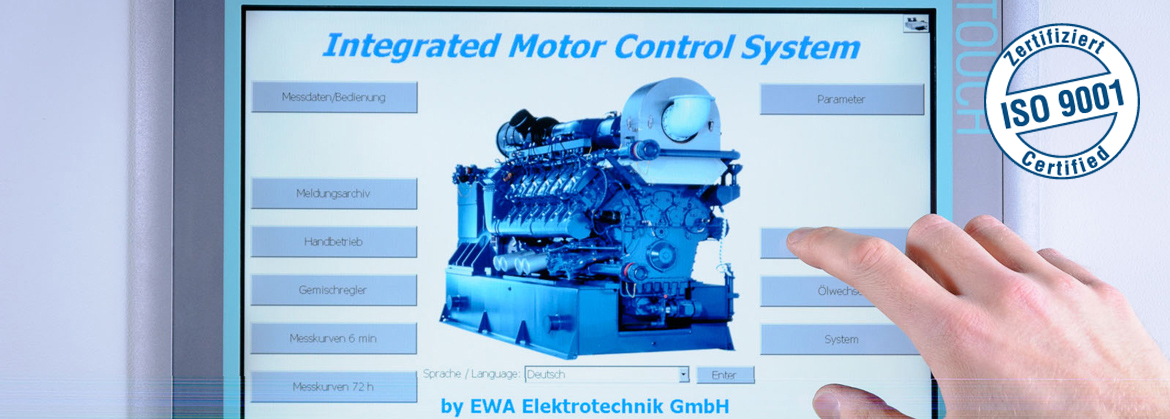

IMCS Integrated Motor Control System

The IMCS is a simple-to-operate and user-friendly integrated engine management system for gas engines.

System overview and functionality

- The control system has been built exclusively on the basis of Siemens components. This ensures fast, long-term availability of spare parts, Siemens EC31 PLC

- 15’’ Siemens full graphic TFT touch panel. Type of protection for front panel: IP 65

- The touch panel is connected to the PLC via a Cat 6 data cable (Industrial Ethernet).

- Start and stop the generator set in Manual and Automatic mode (local/remote)

- 2 repeat start attempts if starting fails

- Control the power of the generator set

- Regulate the mixture with short settling time, for minimising harmful emissions

- Actuate the electronic ignition system with low-voltage distribution, with no mechanical wearing parts

- Actuate the electronic speed governor

- Regulate the temperature of the heating circuit

- Regulate the temperature of the mixture cooling circuit

- Regulate the temperature of the emergency cooling circuit

- Actuate the exhaust bypass valve

- Monitor all measured values and limit switches

- Information on warnings and alarms. Automatic stop in the event of alarms. First-up messages in the event of alarms, to simplify fault finding. Record all messages in an event archive. Display all active messages in a message archive.

- Clear and intuitive control with user guidance using softkeys

- Display measured values, messages, warnings and alarms

Control of the following functions:

- Manual/Automatic mode

- Engine start/stop, generator On/Off, preset power

- Auxiliary drive actuation

- Oil change

- Data acquisition for all important gen-set data, with two simultaneous temporal resolutions with the following features:

- Resolution of one second, recording depth of 6 minutes

- Resolution of 6 minutes, recording depth of 72 hours

- Simultaneous recording of max. 64 values, depending on the number of cylinders

- Recording is automatically stopped in the event of problems, to facilitate fault diagnosis

- Menu-guided selection of curves and graphic display on the touch panel. Data is saved even in the event of power failure.

- Standard interface to the higher-level control system

- Potential-free contacts for requests to the generator set

- 4-20 mA signal for power control

- Potential-free contacts for operation, warning and alarm

- Serial communication with the higher-level master controller or central control system

- Transmission of all important gen-set data (see message specification)

- Receipt of start/stop, nominal power, type of gas, remote acknowledgement

Data transmission to other control systems or computers via RK512 is fail-safe using the popular Siemens procedure 3964R. Standard interface TTY current loop 20 mA (choice of RS232 or RS485)

- Communication with the higher-level master controller or central control system via TCP/IP